Views: 0 Author: Site Editor Publish Time: 2024-03-19 Origin: Site

Recently, the 14th National Winter Games successfully concluded in Hulunbuir City, Inner Mongolia Autonomous Region. The "14th Winter Games" further highlighted the ice and snow features of Hulunbuir, driving the local development of ice and snow cultural tourism. Local construction material companies actively responded to the government's call to participate in ice and snow cultural tourism construction work. Among many construction machinery manufacturers, Qunfeng Machinery stood out, providing high-quality production solutions to clients in Hulunbuir, successfully assisting construction material companies in expanding their production scale, and boosting the economic construction of Hulunbuir.

14th National Winter Games Successfully Concluded

The Wave of Cultural Tourism Leads to High-Quality Development in the Local Construction Material Market

In recent years, Hulunbuir has regarded the cultural tourism industry as the main direction for high-quality development. The traction and radiation effects of the "14th Winter Games" have extensively involved various areas such as urban development and infrastructure construction in Hulunbuir, initiating key cultural tourism construction projects such as the "China Cold Pole Village" and the expansion of the Zhalantun Golden Dragon Mountain Ski Resort.

Construction of the "China Cold Pole Village" Project

Zhalantun Golden Dragon Mountain Ski Resort

The construction of "ice and snow cultural tourism" has driven the development of the local construction material market. A local construction material manufacturer actively approached Qunfeng Machinery, hoping to establish a large-scale automated construction material prefabricated factory to support the construction of cultural tourism facilities in Hulunbuir. After months of hard work by Qunfeng Machinery's technical team and numerous installations and debugging, they created a large-scale fully automatic concrete product production line for the client, effectively aiding the development of local cultural tourism construction work.

Hulunbuir-Qunfeng Large-Scale Fully Automatic Concrete Product Production Line

This production line is Qunfeng's flagship product - the QS1300 concrete product production line, which can achieve intelligent fully automatic production and produce bricks with recycled building waste materials, thus efficiently reducing costs. Equipped with the Qunfeng QMD1200D low-level palletizing production line, it can achieve fully automatic brick stacking and palletizing, automatically generating fork brick holes, and equipped with an automatic pallet return system, making brick stacking more convenient and greatly increasing production efficiency.

Qunfeng Works Alongside Hulunbuir Clients to Build Solid Waste Treatment Centers As a "National Forest City," greenery is the bright background color of Hulunbuir and the substantial base color of high-quality development. Hulunbuir City has always placed the protection of the ecological environment in a dominant position, promoting green transformation in all fields and processes, vigorously developing green roads such as building waste resource utilization and comprehensive solid waste management.

Hulunbuir Urban Greenery

A client in Hulunbuir actively responded to the government's call, hoping to add a solid waste utilization production line to expand production scale and better participate in the green construction of Hulunbuir. After learning about Qunfeng's solid waste brick-making equipment through a series of investigations and comparisons of brands, the client discovered that even when using recycled building waste materials, Qunfeng's QS series concrete forming machines still far exceeded similar products in terms of performance and quality. Ultimately, the client once again purchased a QS1300 concrete block production line from Qunfeng.

Qunfeng QS1300 Concrete Product Forming Machine

The Qunfeng QS series concrete product forming machine is Qunfeng's flagship product for "solid waste brick-making," capable of adapting to various types of recycled building waste materials for brick making. The main machine is equipped with a dual-control rotating feeding system, ensuring uniform feeding and minimizing height differences between bricks before and after production. The vibration table of the main machine is made of military-grade alloy materials, applying "special" welding and heat treatment processes to ensure that the equipment structure has high strength and toughness.

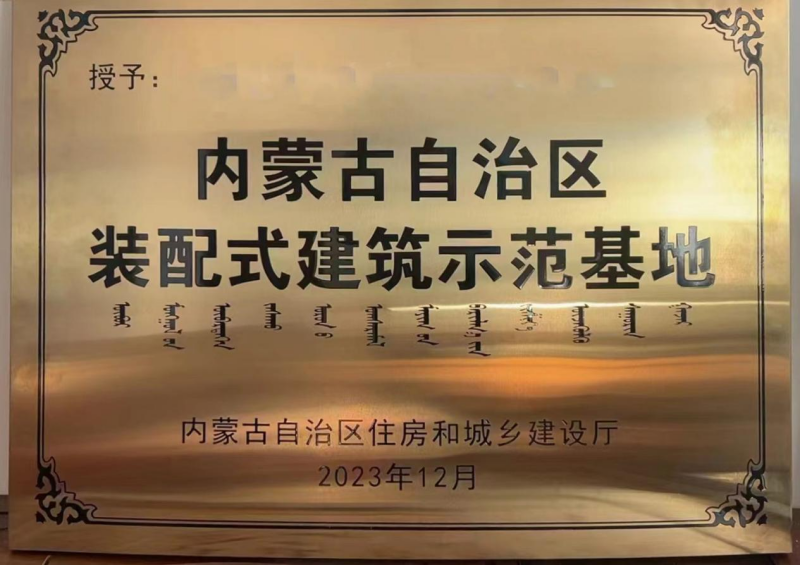

At the January meeting of the Hulunbuir City Housing and Urban-Rural Construction Work Conference, the solid waste treatment center project built by Qunfeng for this client was awarded the title of "Inner Mongolia Autonomous Region Prefabricated Building Demonstration Base" due to its high level of intelligent automation production capacity and mature construction waste resource utilization technology.

Hulunbuir Solid Waste Treatment Center Project Awarded the Title of "Inner Mongolia Autonomous Region Prefabricated Building Demonstration Base"

With the deepening of the national dual-carbon goals and sustainable development strategies, more and more companies are joining the new track of comprehensive utilization of solid waste. So far, Qunfeng has built numerous comprehensive solid waste utilization projects in Zhejiang, Jiangsu, Hubei, Henan, Yunnan, Lhasa, Inner Mongolia, Taiwan, and other places, effectively promoting the level of local comprehensive solid waste utilization. In the future, Qunfeng will continue to devote itself to helping global clients with product analysis and formula guidance, achieving a win-win situation for economic and environmental benefits.

This cuber system is suitable for stacking cured blocks. Generally, it is set independently near the curing yard, and the cured products can be stacked on the spot. It also can be connected directly with block production line to realize the online cuber.

The Terrazzo Tile Machine QPR600-6 is a highly efficient and versatile solution for producing premium terrazzo tiles. Utilizing advanced technology, it ensures precise mixing, molding, and compaction to deliver consistent, high-quality results. This machine is ideal for both small and large-scale production, capable of handling various tile sizes and designs. Built with durability and low maintenance in mind, the QPR600-6 is a reliable choice for businesses aiming to produce decorative, high-quality tiles at competitive prices. Optimized with imported Italian technology, its rotating-disk operation model allows for independent movement, ensuring stability and efficiency. The unique design also allows for further processing of tiles, such as sandblasting, washes, archaizing, and brushed finishes, as well as the production of chromatic or top-colored tiles.

The Road Construction High-Speed Paver Laying Machine is engineered for efficient and rapid asphalt application, ensuring smooth, durable road surfaces. With advanced technology, it combines high-speed operation with precise, consistent results. Built for large-scale paving projects, its robust design minimizes downtime and maximizes productivity. Perfect for highways, roads, and infrastructure projects, this machine also offers versatility in laying various types of bricks, including concrete pavers, water-permeable pavement, and sintered road bricks. It can easily cover 400 to 500 square meters daily, making it an excellent choice for municipal engineering, garden construction, and other paving applications.

The Concrete Batching Machine QPLD1600 3200 2400IV is engineered for efficient and precise measurement and mixing of concrete ingredients. Offering various configuration options, this machine provides flexible solutions to meet diverse batching requirements. It guarantees accurate proportions of aggregates, cement, and water, ensuring consistent and high-quality concrete production. With its durable construction, it is perfectly suited for high-volume operations and can easily integrate into larger concrete production systems. The QPLD1600 3200 2400IV is user-friendly, reduces material waste, and enhances productivity in any concrete manufacturing facility.

The QPL Series Concrete Batching Machine and mixer are fully automated, designed for seamless operation. Featuring electronic cumulative measurement and PLC centralized control with a digital display, the system ensures high measurement precision, quick mixing speeds, and superior reliability. The feeding equipment is highly adaptable, compatible with various machines such as loaders, belt conveyors, grab buckets, and horizontal push systems.

/ / : +86-18150503129

Marketing Center : No.11,Zhitai Road,Quanzhou Economy&Technique Development Zone,Fujian