Views: 0 Author: Site Editor Publish Time: 2025-03-24 Origin: Site

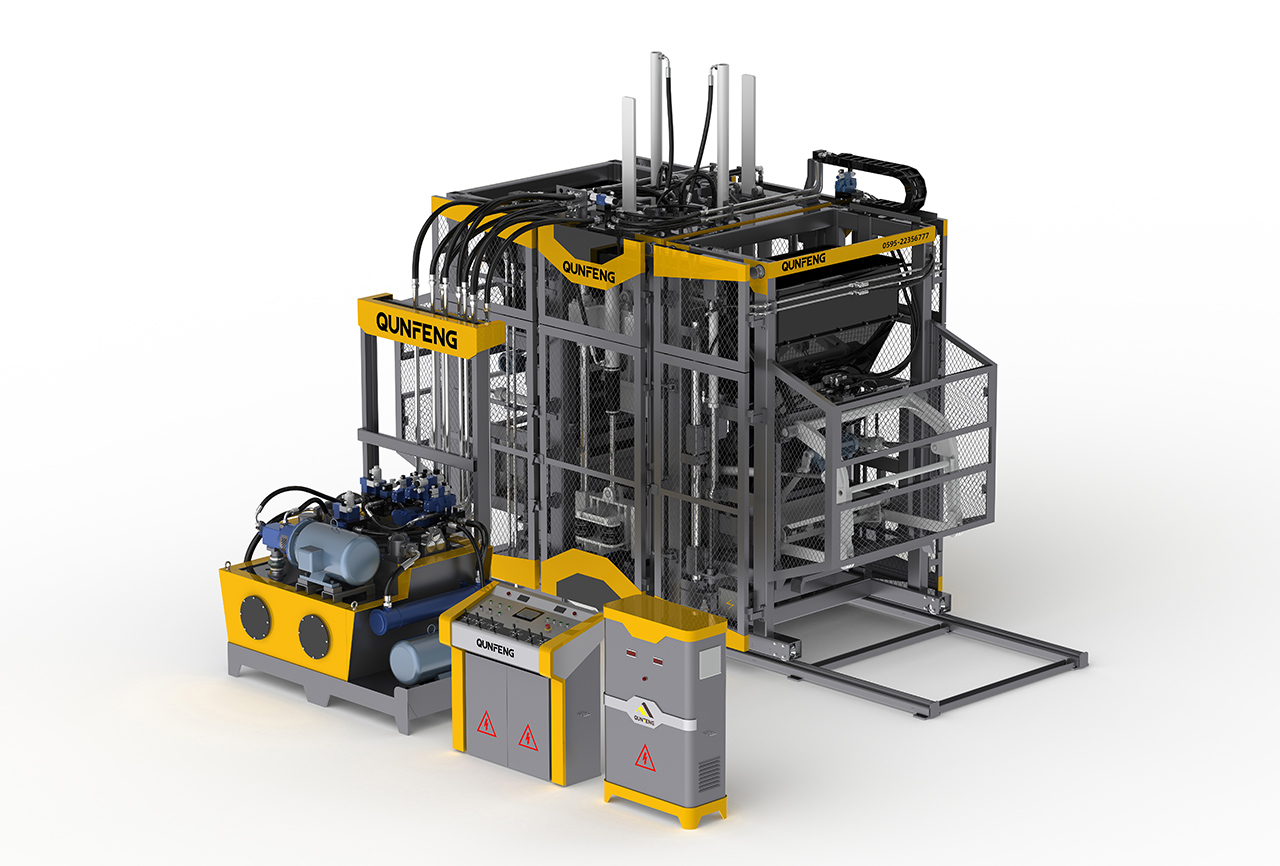

Brick-making machines are a part of construction technology that allows a more efficient, time-saving, and cost-effective effort in the brick-making process. The best option in technology for a brick-making machine is the Qunfeng QS1300-H machine for making bricks that allow for versatility at affordable pricing and extensive rapid production. Qunfeng has been a brick-making machine manufacturer for nearly 30 years and is internationally recognized for its reliable, innovative quality in brick-making endeavors. Qunfeng focuses on providing the best brick-making machines with technologically advanced features that still allow for more efficient production without sacrificing eco-friendly initiatives.

For instance, the Qunfeng QS1300-H machine for making bricks works with a variety of materials and a variety of final brick shapes to allow any manufacturer to use it for any purpose. Bricks are made from various processes and technologies, some quite advanced and in the machine realm. The following aspects are involved in brick-making:

Material Mixing and Preparation

Regardless of what type of bricks are made, the first aspect is raw material preparation. For example, a certain percentage of clay, cement, fly ash, soil, or aggregate is blended to create expected outcomes at the time of blending. Thereafter, when the materials are blended and set, they are sent to the brick molding machine for shaping.

Molding Process

After mixing, the materials enter the molding process, where the final products are formed. Bricks are pressed via hydraulic pressing technology. The pressing force generates a super strong unit with consistent density and consistency.

Vibratory compaction systems

Moreover, many brick pressing machines also utilize vibratory compaction systems to ensure the material settles at the bottom of the mold, compacted for ultimate brick consistency.

Curing System

Bricks are pressed, and a curing process is applied to ensure that they are as solid as they are meant to be. Some brick-making machines come with a curing system that allows for the drying of bricks in a set temperature environment.

Brick Quality Control

For other brick-making machines, the process is fully automated, meaning less human capital is needed. Quality control is performed at the conclusion of the process of making bricks. Automatic brick-making machines incorporate quality control throughout. For instance, bricks are checked for uniformity and strength by sensors with automatic triggering.

The QS1300-H Brick-Making Machine is Qunfeng flagship. This high-end, ultimate machine offers maximum production for all required bricks from a brick-making height of 35mm to 300mm and all in-between units. With an ingenious design, this machine offers the construction industry exactly what's needed for contemporary needs in a powerful, comprehensive, and extensive longevity fashion. This machine will boost production, save costs, and decrease carbon footprint.

High-Efficiency Servo System

An additional feature that distinguishes the QS1300-H is the inclusion of a high-efficiency hydraulic control system. This control system offers remote fault diagnosis and remote maintenance control directly from the machine so the operator can diagnose any potential problems online without needing to disassemble the machine.

Airbag Clamping Reduces Noise

The QS1300-H airbag clamping reduces noise. The component used is an airbag clamping rubber cylinder. Why is this important? Enhanced comfort on the job is essential. Noise is the worst form of pollution. For brick manufacturing, a less intrusive sound helps those making bricks pay attention to their work without distraction.

Airbag Clamping for Reduced Noise

After years of sound pollution in a factory setting, a sound solution is the airbag clamping system on the QS1300-H. Not only is less sound and noise pollution welcomed, but also, quicker mold changeovers make for a more enjoyable work environment and extend the life of molds since accidental breakage is reduced.

The rubber damping pad is made of imported Michelin raw rubber. It boasts exceptional damping and noise attenuation. Thus, it is ideal for maintaining the operational noise levels of the machine during long hours of operation and additional noise from industrial/commercial operations.

Additionally, a rotary feeder for better applicability establishes a consistent in/out setup and reduces processing downtime as materials are fed more reliably. A feeder of this nature promotes extended operational quality capability.

The rotary feeder rotates 360°, which makes it applicable. Therefore, this feeder quality pertains to material blending uniformity that a feeder should possess to provide and optimize quality control of the end product.

The anti-mixing pigment feeding system prevents pigments from unintentionally mixing into other materials when they're sent to appropriate feeders. This quality is essential for pavers for enhanced aesthetic surface quality with consistent color and texture.

Brick manufacturing personalized by Qunfeng just became more professional and hands-off with an intelligent control system that allows operators to control without getting their hands dirty and a dust removal tactile sensor for safety.

Decreased Labor Costs

The primary control hardware is a Siemens PLC, so it's highly reliable. Furthermore, all other components of the system come from similarly reputable German manufacturers like Turck sensors, which provide precise feedback to communicate to operators what's going on. It's simple to use, even for novice users. There is a failure alarm, and self-diagnostic controls make troubleshooting easier, decreasing downtime for decreased productivity as problems can be assessed and understood quickly.

Intellectualized Control System for 15% Reduction in Labor Costs

The QS1300-H features the most intellectualized control system. Thus, it comes with a 15% reduction in labor costs. Since the machine will take care of mold change, vibration failures, and production scheduling, human operators will have to concentrate on more intellectual endeavors, which ultimately require less human interaction and, subsequently, lower labor costs.

Electro-Hydraulic Integrated Technology for Increased Output

The increased electro-hydraulic integration is proprietary to the QS1300-H, which provides a 20% increased output. It provides more energy output for less financial output, which means larger productions for those who wish to run the system in a quicker time setting.

Reduction of Operating Expenses due to Vibration Dampening

The vibration system's suspension type reduces noise production by 10%. This creates a more pleasant working atmosphere, which increases operator safety and efficiency in larger factory environments.

The fault alarm system increases fault detection and reduces fault investigation time by 30%. This is good to keep work on a seamless path without extended delays.

Remote intelligent control is a productivity boost because it minimizes man-in-the-loop error. Essentially, because the system knows what it is doing, how many times it needs to mix, and for how long, human intervention is less frequent. Unfortunately, even if a human tries to intervene with decent intentions, it decreases the overall quality of the output. Therefore, it's a positive component because it reduces operator mistakes.

Remote Intelligent Control enables operators to troubleshoot at any location on the go—diagnosing is a breeze for manufacturers literally on the job anywhere.

Qunfeng has been recognized for years for its high-quality brick-making machines with effective production efficiency, intelligent functionality, and environmental energy projects for the best materials.

Nearly 30 years as an industrial leader, Qunfeng meets the market with automatic integration and creative application, minimizing required manpower and maximizing productivity.

For the last 30 years, Qunfeng has focused on R&D, machine design, and fabrication. The company has sought to improve machine capabilities, and its relationship with industrial social responsibility renders it a favored company for many awards from government and industrial organizations.

The Qunfeng machines come with numerous certifications. They're ISO certified in quality management and environmental management as well as safety production standards, meaning that their machines operate at the anticipated level of management onsite quality and can also guarantee safety and environmental standards needed by other regulatory bodies.

There are several factors to consider when deciding on a brick-making machine for your needs, including:

· Input Material: Machines operate on different input materials to produce bricks—cement, construction waste, tailing or fly ash. Decide your input material and make sure your machine can accommodate it.

· Degree of Automation: Machines can be completely automatic or semi-automatic. Decide based on preference, budget, and production needs.

Qunfeng QS1300-H is a fully automatic brick-making plant that empowers manufacturers to reduce costs and increase output and effectiveness while continuing to provide quality. The QS1300-H will be a welcomed part of any enterprise's operation that is looking to grow its presence in the construction industry with state-of-the-art technology, smart operating systems, and compliance with international standards of energy-saving efforts. Get it today!

This cuber system is suitable for stacking cured blocks. Generally, it is set independently near the curing yard, and the cured products can be stacked on the spot. It also can be connected directly with block production line to realize the online cuber.

The Terrazzo Tile Machine QPR600-6 is a highly efficient and versatile solution for producing premium terrazzo tiles. Utilizing advanced technology, it ensures precise mixing, molding, and compaction to deliver consistent, high-quality results. This machine is ideal for both small and large-scale production, capable of handling various tile sizes and designs. Built with durability and low maintenance in mind, the QPR600-6 is a reliable choice for businesses aiming to produce decorative, high-quality tiles at competitive prices. Optimized with imported Italian technology, its rotating-disk operation model allows for independent movement, ensuring stability and efficiency. The unique design also allows for further processing of tiles, such as sandblasting, washes, archaizing, and brushed finishes, as well as the production of chromatic or top-colored tiles.

The Road Construction High-Speed Paver Laying Machine is engineered for efficient and rapid asphalt application, ensuring smooth, durable road surfaces. With advanced technology, it combines high-speed operation with precise, consistent results. Built for large-scale paving projects, its robust design minimizes downtime and maximizes productivity. Perfect for highways, roads, and infrastructure projects, this machine also offers versatility in laying various types of bricks, including concrete pavers, water-permeable pavement, and sintered road bricks. It can easily cover 400 to 500 square meters daily, making it an excellent choice for municipal engineering, garden construction, and other paving applications.

The Concrete Batching Machine QPLD1600 3200 2400IV is engineered for efficient and precise measurement and mixing of concrete ingredients. Offering various configuration options, this machine provides flexible solutions to meet diverse batching requirements. It guarantees accurate proportions of aggregates, cement, and water, ensuring consistent and high-quality concrete production. With its durable construction, it is perfectly suited for high-volume operations and can easily integrate into larger concrete production systems. The QPLD1600 3200 2400IV is user-friendly, reduces material waste, and enhances productivity in any concrete manufacturing facility.

The QPL Series Concrete Batching Machine and mixer are fully automated, designed for seamless operation. Featuring electronic cumulative measurement and PLC centralized control with a digital display, the system ensures high measurement precision, quick mixing speeds, and superior reliability. The feeding equipment is highly adaptable, compatible with various machines such as loaders, belt conveyors, grab buckets, and horizontal push systems.

/ / : +86-18150503129

Marketing Center : No.11,Zhitai Road,Quanzhou Economy&Technique Development Zone,Fujian