| Availability: | |

|---|---|

| Quantity: | |

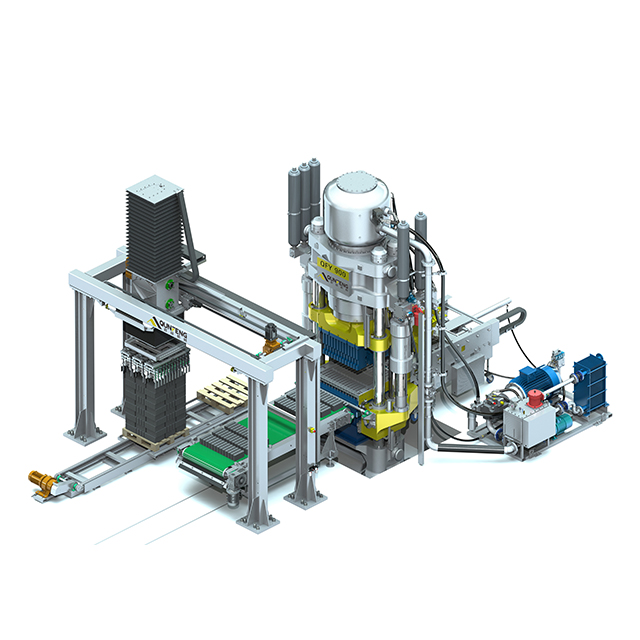

QP900

Qunfeng

Product Description

Main Featured of the Advanced Block Machine | |||

| |||

Features:: Using static pressure forming technology, it can press various brick types such as standard bricks, blind bricks, through hole blocks, and large blocks. Main Technical Features: 1. Static pressure forming, energy saving and high efficiency: pallet-free automatic static pressure forming, no pollution, low noise. The constant power variable pump is used to provide the power source for the system, and the output energy of the pump is automatically adjusted according to the actual working conditions, and equipped with a more optimized hydraulic control system, the whole machine is more energy-saving and efficient; 2. Equivalent two-way pressurization and high productivity: brick forming adopts the equivalent two-way pressurization method of main oil cylinder pressurization and demoulding cylinder follow-up, high brick compactness, good quality and high productivity; 3. Rotary palletizer: the bricks cross each other at 90° layer by layer, and the stacking stability is good; 4. Advanced and reliable control system: Adopt closed-loop control technology of servo proportional valve, linear displacement sensor and servo motor, optimize and improve the control system, strong anti-interference ability, fast response, pressure and position control precisley; 5. Wide adaptability: various optional material distribution methods and large-stroke demoulding oil cylinder, the brick press machine can be applied to a variety of bricks with different raw materials and different specifications. |

| QP900 | TECHNICAL DATA |

Max.Pressure (KN) | 9000 |

Max. Demoulding Force(KN) | 2000 |

Max. Height Of Mould Frame(mm) | 350 |

Max. Pressure Of Main Cylinder (MPa) | 32 |

| Suitable height for block(mm) | 60-190 |

Pallet size(mm) | Pallet free |

| Compression form | double press |

| Cycle time(s) | 15-17 |

| Power(kw) | 102.1 |

| Main equipment dimensions(mm) | 4700*4600*6100 |

| Legend | Product size (mm) | Pcs./Pallet | ||

| 240*115*53 | 39 | |||

240*115*90 | 18 | |||

| 390*190*190 | 8 | |||

Note: The moulding cycle time and the hourly capacity will be changed according to the proportion and the quality of the raw matirlal.

This cuber system is suitable for stacking cured blocks. Generally, it is set independently near the curing yard, and the cured products can be stacked on the spot. It also can be connected directly with block production line to realize the online cuber.

QPR600-6 Terrazzo Tile Machine is optimized on the basis of imported Italian technology. It owns rotating-disk type operation model which makes the movement independent, and it has the features of stable structure and high efficiency. Due to its unique design concept, the tile can carry on further processing after production, such as sandblasting, washes, archaizing, brushed processing. It can aslo produce chromatic tile or top-colored tile.

QS1300-H is currently Qunfeng’s best-selling model, which can adapt to the production of bricks with a height of 35-500mm and has a wider application range.

QS1300-H is currently Qunfeng’s best-selling model, which can adapt to the production of bricks with a height of 35-500mm and has a wider application range. Its vibration system adopts high-efficiency two-axis servo system, high speed, high frequency vibration, energy saving and noise reduction, low inertia ejection and vibration, realizing super-speed acceleration molding; with auxiliary automatic mold change, it can realize semi-automatic and rapid mold change .

New-type Paver Laying Machine is suitable for the pavement, tree lawn, garden trails, squares and other places to pave concrete paver brick, water permeable pavement, sintering brick road brick, etc..Laying brick types are including L pattern, herringbone pattern, linear pattern and fancy double linear pattern and so on. It can easily to work 400 ~ 500 square meters of paving per day, which is an ideal machine for municipal engineering and garden construction.

Automatic pallet provider can automatically arrange the unordered pallets in the working site and then send the pallet to pallet feeder of block production line for recycling use.

/ / : +86-18150503129

Marketing Center : No.11,Zhitai Road,Quanzhou Economy&Technique Development Zone,Fujian