| Availability: | |

|---|---|

| Quantity: | |

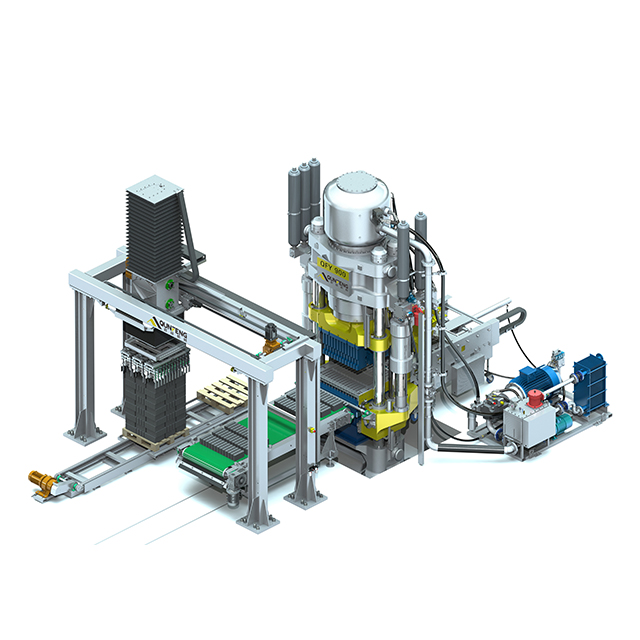

QP900

Qunfeng

Product Description

Main Featured of the Advanced Block Machine | |||

| |||

Features: Using static pressure forming technology, it can press various brick types such as standard bricks, blind bricks, through hole blocks, and large blocks. Main Technical Features: 1. Static pressure forming, energy saving and high efficiency: pallet-free automatic static pressure forming, no pollution, low noise. The constant power variable pump is used to provide the power source for the system, and the output energy of the pump is automatically adjusted according to the actual working conditions, and equipped with a more optimized hydraulic control system, the whole machine is more energy-saving and efficient; 2. Equivalent two-way pressurization and high productivity: brick forming adopts the equivalent two-way pressurization method of main oil cylinder pressurization and demoulding cylinder follow-up, high brick compactness, good quality and high productivity; 3. Rotary palletizer: the bricks cross each other at 90° layer by layer, and the stacking stability is good; 4. Advanced and reliable control system: Adopt closed-loop control technology of servo proportional valve, linear displacement sensor and servo motor, optimize and improve the control system, strong anti-interference ability, fast response, pressure and position control precisley; 5. Wide adaptability: various optional material distribution methods and large-stroke demoulding oil cylinder, the brick press machine can be applied to a variety of bricks with different raw materials and different specifications. |

| QP900 | TECHNICAL DATA |

Max.Pressure (KN) | 9000 |

Max. Demoulding Force(KN) | 2000 |

Max. Height Of Mould Frame(mm) | 350 |

Max. Pressure Of Main Cylinder (MPa) | 32 |

| Suitable height for block(mm) | 60-190 |

Pallet size(mm) | Pallet free |

| Compression form | double press |

| Cycle time(s) | 15-17 |

| Power(kw) | 102.1 |

| Main equipment dimensions(mm) | 4700*4600*6100 |

| Legend | Product size (mm) | Pcs./Pallet | ||

| 240*115*53 | 39 | |||

240*115*90 | 18 | |||

| 390*190*190 | 8 | |||

Note: The moulding cycle time and the hourly capacity will be changed according to the proportion and the

quality of the raw matirlal.

This cuber system is suitable for stacking cured blocks. Generally, it is set independently near the curing yard, and the cured products can be stacked on the spot. It also can be connected directly with block production line to realize the online cuber.

The Terrazzo Tile Machine QPR600-6 is a highly efficient and versatile solution for producing premium terrazzo tiles. Utilizing advanced technology, it ensures precise mixing, molding, and compaction to deliver consistent, high-quality results. This machine is ideal for both small and large-scale production, capable of handling various tile sizes and designs. Built with durability and low maintenance in mind, the QPR600-6 is a reliable choice for businesses aiming to produce decorative, high-quality tiles at competitive prices. Optimized with imported Italian technology, its rotating-disk operation model allows for independent movement, ensuring stability and efficiency. The unique design also allows for further processing of tiles, such as sandblasting, washes, archaizing, and brushed finishes, as well as the production of chromatic or top-colored tiles.

The Road Construction High-Speed Paver Laying Machine is engineered for efficient and rapid asphalt application, ensuring smooth, durable road surfaces. With advanced technology, it combines high-speed operation with precise, consistent results. Built for large-scale paving projects, its robust design minimizes downtime and maximizes productivity. Perfect for highways, roads, and infrastructure projects, this machine also offers versatility in laying various types of bricks, including concrete pavers, water-permeable pavement, and sintered road bricks. It can easily cover 400 to 500 square meters daily, making it an excellent choice for municipal engineering, garden construction, and other paving applications.

The Concrete Batching Machine QPLD1600 3200 2400IV is engineered for efficient and precise measurement and mixing of concrete ingredients. Offering various configuration options, this machine provides flexible solutions to meet diverse batching requirements. It guarantees accurate proportions of aggregates, cement, and water, ensuring consistent and high-quality concrete production. With its durable construction, it is perfectly suited for high-volume operations and can easily integrate into larger concrete production systems. The QPLD1600 3200 2400IV is user-friendly, reduces material waste, and enhances productivity in any concrete manufacturing facility.

The QPL Series Concrete Batching Machine and mixer are fully automated, designed for seamless operation. Featuring electronic cumulative measurement and PLC centralized control with a digital display, the system ensures high measurement precision, quick mixing speeds, and superior reliability. The feeding equipment is highly adaptable, compatible with various machines such as loaders, belt conveyors, grab buckets, and horizontal push systems.

/ / : +86-18150503129

Marketing Center : No.11,Zhitai Road,Quanzhou Economy&Technique Development Zone,Fujian