| Availability: | |

|---|---|

| Quantity: | |

QS1000

Qunfeng

Product Description

Main Featured of the Advanced Block Machine | |||

| |||

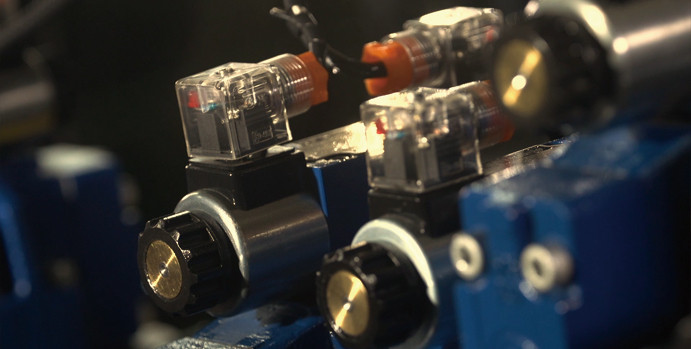

Main features of the product High-efficiency servo system: using high-efficiency two-axis servo, high speed, high frequency vibration can be realized, good synchronization, energy saving and noise reduction; High-efficiency hydraulic control system: It is driven by a high-horsepower double-pump motor, which has high efficiency, can achieve flexible movements and quick response to actions; Airbag clamping: reduce sound and noise, increase the speed of mold change, and reduce mold damage; Damping pad: rubber pad made of imported Michelin raw rubber, high-efficiency damping and noise reduction, durable; Double pressure head cylinder design: effectively improve the strength and quality of products; Rotary feeder: 360°rotating rake, equipped with scraping device, wide applicability, especially good for making high-quality tiles; Anti-mixing pigment feeding system: while anti-mixing, it effectively improves the surface quality of the tiles; Auxiliary automatic mold changing system: realize quick mold change and effectively improve production efficiency; Intelligent control: The core hardware of the control system adopts Siemens PLC, and the remaining sensor components adopt well-known brands such as German Turck; the operation is simple and easy to understand; it has a full range of fault alarm system and automatic diagnosis functions, which greatly shortens the troubleshooting time. |

9 major components for the servo block machine | ||

Efficient Servo System |  Stabile Hydraulic System |

Dumping Airbag |

The design for the press head with two oil cylinders |

Air-operated Clean Device |

Ping-pong type for feeding material |

Arc-shape Feeding Arm |

Modularize Eccentric Vibration |

Automatic Control System |

| 1.Intellectualized control, 15% saving in labor cost . 2.Electro-Hydraulic integrated technology , 20% raising in output; 3.Suspension Type Vibration, 10% reduce in noise pollution; 4.Fault Alarm System, 30% time saving in troubleshooting; 5.Intellectualized Starting,20% improvement in working efficiency 6.Material-Ratio program saved in PLC controller, no human disturbance. 7.Intelligent remote control ,quickly solve the problem in all the places at any time. 8.Customized design, efficient production that reduces costs. |

| QS1000 | TECHNICAL DATA |

Dimension(Main Machine) | 3135X2480X3490mm |

Rating pressure | 21MPa |

| Vibration frequency | 0-75HZ |

Vibration | Table vibration |

| Pallet size | 1100x760mm |

suitable height for block | 35-300mm |

| Cycle time | 9.5-20sec |

Power | 51.6kW |

| Legend | Product size (mm) | Pcs./Pallet | ||

| 240*115*53 | 44 | |||

200*100*60 | 27 | |||

225*112.5*60 | 24 | |||

390*190*190 | 7 | |||

| 400*200*200 | 7 | ||

Note: The moulding cycle time and the hourly capacity will be changed according to the proportion and the quality of the raw matirlal.

Production Line

Simple Block Making Production Line(Single line) | ||||

|

Fully Automatic Block Making Production Line | ||||

|

Fully Automatic Block Production line with Curing Rack | ||||

|

Application

Building Wall Material Series | ||

Flower Bed Brick |  Split Brick |  Split Brick |

Split Brick |  Wall Brick |  Solid Brick |

Paving Stone Series | |||

Permeable Brick |

|

Antique Brick |

Antique Brick |

Antique Brick |

Antique Brick |

Chain Pavement |

Chain Pavement |

Pavement Brick |

Antique Brick |

Antique Brick |

|

|

|

|

Split Brick, Pavement Brick |

Grass Brick |

Grass Brick |

Paving Stone |

Paving Stone |

Paving Stone |

Paving Stone |

Paving Stone |

Paving Stone |

Paving Stone |

Paving Stone |

Paving Stone |

Paving Stone |

Road Wdge Stone Series | |||

Road Wdge Stone |

Road Wdge Stone |

Road Wdge Stone |

Road Wdge Stone |

Road Wdge Stone |

Road Wdge Stone |

Road Wdge Stone | |

Slope-protect Brick Series | |||

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick | ||

Customer Case

Gansu |

India | ||

Mozambique |

IvoryCoast | ||

Lianyungang |

Nantong |

This cuber system is suitable for stacking cured blocks. Generally, it is set independently near the curing yard, and the cured products can be stacked on the spot. It also can be connected directly with block production line to realize the online cuber.

The Terrazzo Tile Machine QPR600-6 is a highly efficient and versatile solution for producing premium terrazzo tiles. Utilizing advanced technology, it ensures precise mixing, molding, and compaction to deliver consistent, high-quality results. This machine is ideal for both small and large-scale production, capable of handling various tile sizes and designs. Built with durability and low maintenance in mind, the QPR600-6 is a reliable choice for businesses aiming to produce decorative, high-quality tiles at competitive prices. Optimized with imported Italian technology, its rotating-disk operation model allows for independent movement, ensuring stability and efficiency. The unique design also allows for further processing of tiles, such as sandblasting, washes, archaizing, and brushed finishes, as well as the production of chromatic or top-colored tiles.

The Road Construction High-Speed Paver Laying Machine is engineered for efficient and rapid asphalt application, ensuring smooth, durable road surfaces. With advanced technology, it combines high-speed operation with precise, consistent results. Built for large-scale paving projects, its robust design minimizes downtime and maximizes productivity. Perfect for highways, roads, and infrastructure projects, this machine also offers versatility in laying various types of bricks, including concrete pavers, water-permeable pavement, and sintered road bricks. It can easily cover 400 to 500 square meters daily, making it an excellent choice for municipal engineering, garden construction, and other paving applications.

The Concrete Batching Machine QPLD1600 3200 2400IV is engineered for efficient and precise measurement and mixing of concrete ingredients. Offering various configuration options, this machine provides flexible solutions to meet diverse batching requirements. It guarantees accurate proportions of aggregates, cement, and water, ensuring consistent and high-quality concrete production. With its durable construction, it is perfectly suited for high-volume operations and can easily integrate into larger concrete production systems. The QPLD1600 3200 2400IV is user-friendly, reduces material waste, and enhances productivity in any concrete manufacturing facility.

The QPL Series Concrete Batching Machine and mixer are fully automated, designed for seamless operation. Featuring electronic cumulative measurement and PLC centralized control with a digital display, the system ensures high measurement precision, quick mixing speeds, and superior reliability. The feeding equipment is highly adaptable, compatible with various machines such as loaders, belt conveyors, grab buckets, and horizontal push systems.

/ / : +86-18150503129

Marketing Center : No.11,Zhitai Road,Quanzhou Economy&Technique Development Zone,Fujian