Views: 0 Author: Site Editor Publish Time: 2025-03-25 Origin: Site

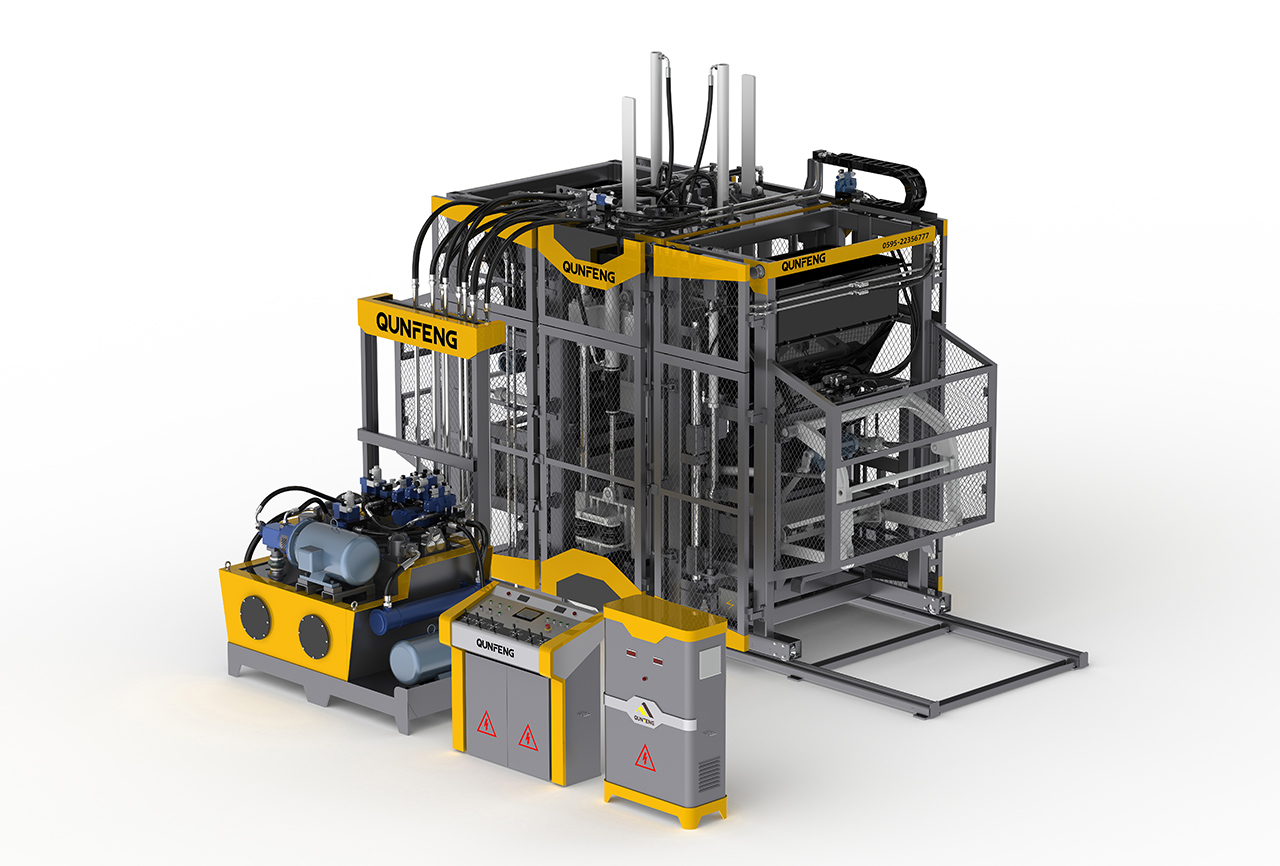

There is no better way to ensure the consistent and productive operation of a brick and concrete block plant than through operational effectiveness via an efficient, reliable, and high-achieving machine. While many machines exist on the market today, one of the most reliable, reviewed, and recommended machines across the globe is the Qunfeng QS1300-H Brick Making Machine. Utilizing such a high-tech, high-efficiency machine in one's arsenal of a brick-making plant will only bolster effectiveness and achievement in the brick/block construction and manufacturing industry.

Fujian Qunfeng Machinery Co., Ltd. has always been a leader in the research and development, production, and sales of construction material machinery such as concrete block making line, AAC block production line, and cement block making machines. Among our top sold products is the QS1300-H Brick Manufacturing Machine; this concrete block machine for sale is real, produces incredible output, and comes with exceptionally advanced features.

The QS1300-H Brick Making Machine comes from the Qunfeng pedigree. Qunfeng is a technologically advanced enterprise in the building material machinery industry. Qunfeng has been known for creating better machines for the foreseeable future. Qunfeng brick-making machine is the best brick-making machine for any brick production line for the following reasons:

Advanced Technology Integration

It's easy to see why Qunfeng machines stand the test of time and are so technologically advanced. Qunfeng merges intelligent technology with high efficiency. For instance, the QS1300-H features a high-efficiency two-axis servo system that creates ultra-high speeds and vibrations at highly frequent levels. Thus, brick making occurs at a quicker pace with standard compliance; it's less energy-consuming and has lower decibels, which is a technologically savvy approach that fosters lower operational costs and greater productivity.

Increased Production Efficiency

Another unique feature of the QS1300-H is its semi-automatic mold change system. The quick, easy mold changing procedure reduces wait time between production and increases efficiency. In addition, the machine can produce bricks from 35 to 300mm in height, making it versatile for construction needs.

Environmental Responsibility

Qunfeng understands the global shift towards greener operations. For example, the QS1300-H Brick Making Machine features noise-reduction technology, including damping pads and airbag clamping that enhance machine functionality but simultaneously lower sound emissions—one of the typical byproducts of industrial machinery.

The manufacturer and type of brick-making machine you choose will optimize or undermine your budgetary concerns, quality, and productivity. Qunfeng is a worldwide supplier of building material machinery with consideration to the following characteristics of its brick-making machines, including the QS1300-H:

Trusted Global Brand

Qunfeng is a global brand with more than 10000 clients across 120 nations and territories. Its brick-making machinery is dependable, cutting-edge, and productive. Qunfeng possesses its R&D team in the realm of construction material machinery. Thus, it understands every aspect of operating any machine it sells.

Robust and Efficient Manufacturing

Qunfeng has a workshop spanning 215,000 square meters which enables them to do extensive mass productions while also maintaining quality control to the point where they guarantee each machine individually. Qunfeng possesses over 300 national patents, which showcases their abilities to create innovative developments in the arena that are matched by none, and they've proven this to be true time and time again.

Advanced Technology Of The Models

The QS1300-H comes with the following advanced technology:

· The yield of electro-hydraulic integrated technology

· Worked by intelligent control system PLC of Siemens

· Suspension-type vibrating system to reduce sound pollution

· High-efficiency servo system - reduced machine downtime.

· High speed multi-position hydraulic cylinder - accurate assembly.

· Vibration in accordance with European standards - excellent reliability.

· Component used with electrical features - ensured functionality.

4. Dual Axis Servo System

The QS1300-H comes with a dual axis/servo system that produces high speed/high frequency vibration, leading to quicker production and consistent density of blocks. In addition, servo technology provides a type of offset operation that is energy efficient for the machine and simultaneously minimizes noise and vibrations.

Strong Hydraulic Control System

The hydraulic system works with a high horsepower double pump motor, which ensures flexible movement/lively response to actions. This means that the strong hydraulics allow the operator to have better control since the machine can respond to desired actions, which maintains brick integrity and uniform qualities.

Airbag Clamping System

The airbag clamping system reduces operating noise and increases mold changing speed. For those factories that have to frequently change brick molds, this is a tremendous advantage. It also reduces mold wear, meaning this machine will be up and running for that much longer.

Auxiliary Automatic Mold Changing System

The automatic mold changing system ensures that with the QS1300-H, mold changing occurs faster and easier. Therefore, this increases production efficiency significantly, for less time is lost during the changing process.

Qunfeng Machinery Co., Ltd. Longer nearly thirty years in business; reputable for quality and efficient production. They manufacture an expansive range of products and consistently improve upon what's already in the field to ensure their products are up-to-date. Qunfeng is the recipient of several recent certifications and reputable accomplishments over the last few years by this company, which suggest an attention to detail for quality and inventive endeavors. For example, Qunfeng has quality management system certifications and environmental management system certifications. Furthermore, Qunfeng has safety production standard certifications, meaning this company possesses the most reputable standards in safety of production quality as well as environmental quality.

Ideally, the only thing standing between you and your brick-making desires is selecting the best brick machine. From an overall investment, long-term savings, and durability for your investment needs, the best brick machine to operate for all your brick making needs is the Qunfeng QS1300-H as it has the highest levels of modern technology, productivity, and cost-effective endeavors while producing quality bricks in short amounts of time for your quality brick needs. For any factory operator, this machine contains energy-saving features, bricks produced quickly, and a user-friendly control board.

The Qunfeng QS1300-H. You'll note from Industry Q&A that Qunfeng has been a top brand in the brick-making machine industry nearly 30 years, with the brand ranking for quality brick machines and a reputable brand. If you're looking to improve efficiency, reduce price, or improve brick value, the QS1300-H Brick Making Machine is for you.

Best Brick-Making Machine for Your Business: The Qunfeng QS1300-H

Of all the brick-making machines available, the Qunfeng QS1300-H stands out as one of the top choices for many small- to large-scale brick production endeavors. Here's why one of the most used machines worldwide is the Qunfeng QS1300-H:

Advanced Technology for Higher Efficiency

Enhanced Production Rates Through Technological Transference

The QS1300-H features a high-efficiency servo system that provides machine operators with proprietary vibrational capabilities. In addition to high speed and high frequency vibration abilities, this machine also boasts low power consumption whilst giving operators the peace of mind that every brick will be uniformly compacted, thus making them stronger and denser.

Semi-Automatic Mold Change for Better Productivity

This machine is quiet. Power consumption for the parts is only 0.1 HP and therefore isn't loud unless forced to be through overuse or stress. The effective working area of the vibration plate is relatively large, meaning that the structural output dimensions all react to vibration without added sound. The drive gearbox has a gear ratio of 4:1, meaning that there is less stress and noise output when connected and adjusted properly. The vibrators run at a speed of 8,500 r/min, which is fast but does not indicate further noise output beyond the capacity of the machine.

Intelligent Control System

The Qunfeng QS1300-H is designed for durable, long-lasting use. For example, Michelin rubber damping pads facilitate sound dampening; the construction of the machine is designed with hydraulic press technology. These operational durable features reduce the need for maintenance throughout the lifespan of the brickmaker.

Durable and Low Maintenance

All you need to know to buy a brick manufacturing machine. Choosing the right durable brick-making machine for your project guarantees the quality of generated materials and relative production expenses.

This machine is popular in the market as many flourishing brick factories use this brand. This brick machine is known for its advanced technology, high efficiency, and stable operation. This brick machine is a mold change semi-automation with automatic intelligent control and energy-saving control. The QS1300-H brick machine is suitable for medium and large scale brick production. For any additional details about this machine or any of the machines, contact Qunfeng Machinery to see how our cutting-edge machines can change your bricks factory.

This cuber system is suitable for stacking cured blocks. Generally, it is set independently near the curing yard, and the cured products can be stacked on the spot. It also can be connected directly with block production line to realize the online cuber.

The Terrazzo Tile Machine QPR600-6 is a highly efficient and versatile solution for producing premium terrazzo tiles. Utilizing advanced technology, it ensures precise mixing, molding, and compaction to deliver consistent, high-quality results. This machine is ideal for both small and large-scale production, capable of handling various tile sizes and designs. Built with durability and low maintenance in mind, the QPR600-6 is a reliable choice for businesses aiming to produce decorative, high-quality tiles at competitive prices. Optimized with imported Italian technology, its rotating-disk operation model allows for independent movement, ensuring stability and efficiency. The unique design also allows for further processing of tiles, such as sandblasting, washes, archaizing, and brushed finishes, as well as the production of chromatic or top-colored tiles.

The Road Construction High-Speed Paver Laying Machine is engineered for efficient and rapid asphalt application, ensuring smooth, durable road surfaces. With advanced technology, it combines high-speed operation with precise, consistent results. Built for large-scale paving projects, its robust design minimizes downtime and maximizes productivity. Perfect for highways, roads, and infrastructure projects, this machine also offers versatility in laying various types of bricks, including concrete pavers, water-permeable pavement, and sintered road bricks. It can easily cover 400 to 500 square meters daily, making it an excellent choice for municipal engineering, garden construction, and other paving applications.

The Concrete Batching Machine QPLD1600 3200 2400IV is engineered for efficient and precise measurement and mixing of concrete ingredients. Offering various configuration options, this machine provides flexible solutions to meet diverse batching requirements. It guarantees accurate proportions of aggregates, cement, and water, ensuring consistent and high-quality concrete production. With its durable construction, it is perfectly suited for high-volume operations and can easily integrate into larger concrete production systems. The QPLD1600 3200 2400IV is user-friendly, reduces material waste, and enhances productivity in any concrete manufacturing facility.

The QPL Series Concrete Batching Machine and mixer are fully automated, designed for seamless operation. Featuring electronic cumulative measurement and PLC centralized control with a digital display, the system ensures high measurement precision, quick mixing speeds, and superior reliability. The feeding equipment is highly adaptable, compatible with various machines such as loaders, belt conveyors, grab buckets, and horizontal push systems.

/ / : +86-18150503129

Marketing Center : No.11,Zhitai Road,Quanzhou Economy&Technique Development Zone,Fujian