Views: 0 Author: Site Editor Publish Time: 2025-03-24 Origin: Site

Hydraulic Pressure Vibration is a new technology that pertains to an aspect of the vibrations used in block forming. Hydraulic Pressure Vibration allows for a greater range of vibration control during the block-making process. Not only does the vibration happen at standardized intervals, but the ability to control the depth and width of vibrations per hydraulic pressure means the vibrations can be avoided in certain areas while encouraged in others. This depth and breadth of hydraulic vibrations are essential for industrial-grade block creation.

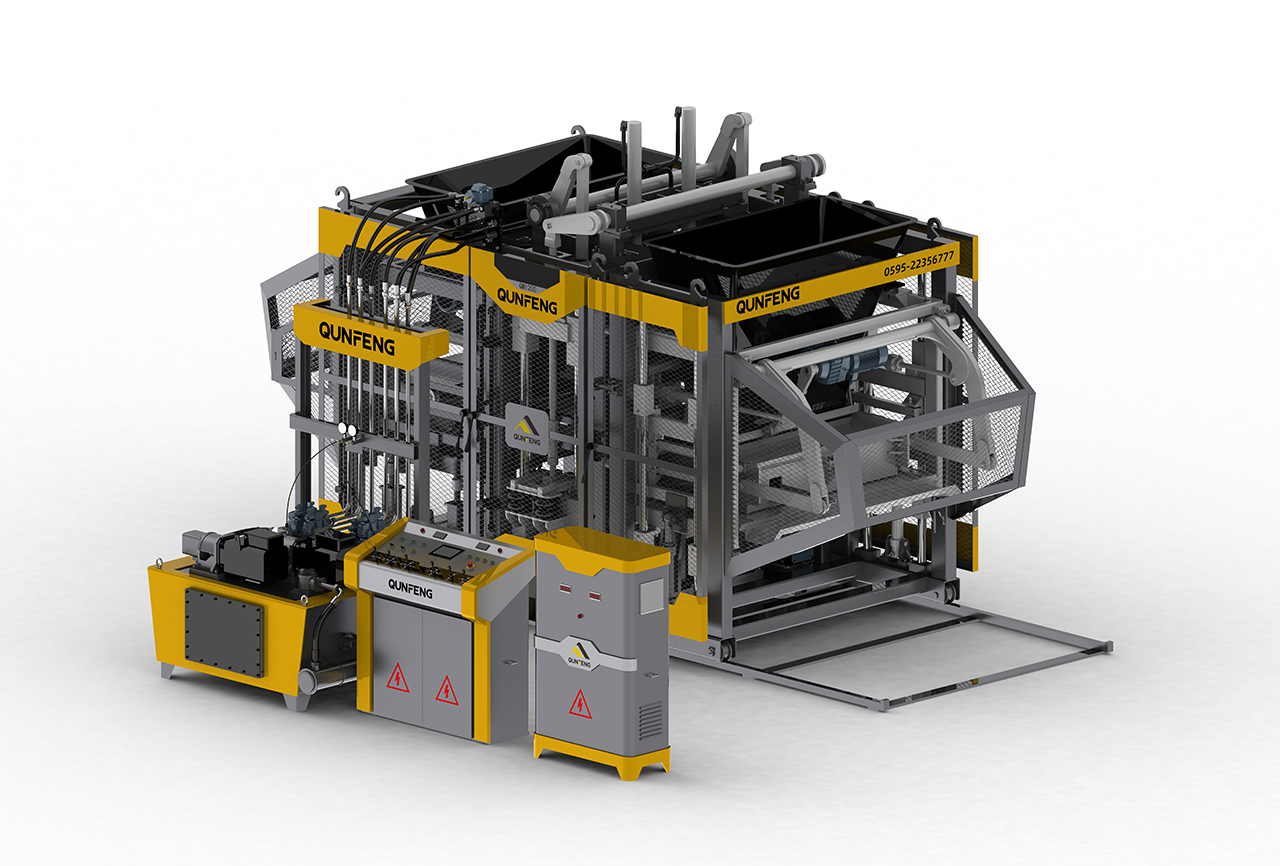

Another important feature of the QM1200 Block Machine is its U-shaped vibration. This is a patented technology from Qunfeng that enables a non-table vibrated machine and greatly surpasses the quality characteristics of standard blocks made from a table vibration machine. The QM1200 is equipped with this U-shaped vibration to promote noise reduction, expected molding rate, and productivity efficiency, as well as to guarantee a density of the final crafted products that is heavy and solid for any construction project. This machine decreases the sound quality of more traditional machines, which means that the process of making blocks is faster, more industrialized, and done in a more refined, quiet environment.

Another critical enhancement that sets the QM1200 apart is the anti-mixture color feeding system, which enhances the paver's surface quality. The anti-mixture color feeding system ensures that different materials do not mix when blocks are made, leading to a more uniform and consistent surface of blocks of high quality. Therefore, companies that use blocks for aesthetic purposes benefit from this feature, as it guarantees the color and texture are uniform. Therefore, the anti-mixture is a great enhancement.

The clamping system in comparison to the airbag clamping of the QM1200, involves quieter operation and longer tooling life. The airbag generates a uniform and powerful clamping pressure that supports the precise positioning required for the process to move forward successfully, thus generating better-formed blocks and extending the life of the tooling.

In addition, an upgraded noise-dampening capability from the airbag clamping system presents a more gratifying operator experience. A quieter job site is an easier job site, and when workers are more comfortable, they're happier. This mold will last longer, requiring less maintenance and costs for mold replacement down the line.

Imported shock pads come standard in the QM1200 Block Making Machine. Shock pads are required for shock, vibration, and noise reduction. The better-quality shock pad, the more sound and vibration reduction occur during operation, which adds to the quieting capacity and increases the longevity of the product.

The QM1200 imports shock pads and vibration dampening from elsewhere, which maintains these qualities over time without adjustment. An added focus on weight transfer on unnecessary pressure points adds to its durability and non-failure over time. Thus, compared to comparable machines, this machine will be a worthwhile investment over time.

Industrial durability characterizes the QM1200 Block Machine. The block-making cycle is between 10 to 22 seconds, meaning this machine can pump them out in a literal blink of an eye. For those who own a larger-scale operation when it comes to construction, these time ranges streamline project requirements all the more as they don't need to worry about time constraints and productivity expectations because this machine exceeds all operational and time efficiency expectations.

Of course, these cycle times are achieved unaltered by the quality of the final product—it's the opposite; in fact, one can have the best of both worlds.

The QM1200 has machine dimensions of 3510 x 2700 x 3250 mm, which indicates that this is a heavy-duty option for block production. This means that the machine is not likely to be moved often, as it runs at such high capacity and productivity levels that it does not generate excess vibration during operation.

The QM1200 is meant to last a long time. The materials and construction of the machine show that it operates under highly intensive forces and load-bearing requirements and still turns out quality blocks. Any operation looking to reduce wear and tear on machines while generating high levels of output and quality blocks will find this machine surpasses expectations. The QM1200 is incredibly powerful and productive with its block height range of 50 to 220 mm. Therefore, it doesn't just produce standard blocks, but it also sets the foundation for paving stones or hollow blocks; this concrete block machine can fulfill all the various concrete product requirements for essential construction endeavors.

Moreover, being able to customize the height of the product is required for companies to satisfy essential construction requirements from low-height industrial building basements to high-height commercial buildings.

The QM1200 Block Making Machine needs a pressure requirement of 21 MPa and a vibration frequency of 0-75 Hz. An energy requirement of 69 kW is relatively low for such great energy results. It's also very impressive, guaranteeing this machine is energy efficient since it doesn't require high energy output for desirable performance. Therefore, this machine is a great option for environmental considerations and energy saving in the plant.

The QM1200 pallet size is 1360x700mm because where the world is a small place and innovation happens, the more companies can save space and efficiency in material handling, the better the parts can be accommodated within a machine's space and connected to existing systems.

You need to maintain a block-making machine to ensure it lasts. This means cleaning the block mold, assessing the hydraulic systems, and changing out worn parts. This way, performance levels are maintained, and no downtime occurs.

Cost Saving

Maybe the greatest cost-saving advantage of buying a block making machine is reduced labor needs. Automatic and semi-automatic machines reduce manual labor needs, which translates to increased efficiency and reduced operational expenses. In addition, machines optimize raw material usage, so there is less wastage, which translates to greater profits.

Versatility

The variations in the machines and the end products are just as astonishing. The machines make every kind of block from paving blocks to fly ash blocks to solid to hollow, and they can be found on any construction site from residential to highway to educational institutions to medical facilities.

Environmentally Sustainable Impact

Like the many new upstart companies looking to save their own on environmentally sustainable construction options, the fly ash block making machine is not that difficult to find either, as companies look to repurpose industrial waste products and use less natural resources as the components for high-quality blocks.

Block Making Machine Price

Curious about the block making machine price? This all depends on the machine you need and how you plan to have it operate. The more automatic capabilities may increase your initial investment, but it also increases efficiency and output.

Block Making Machine Suppliers

Block making machine price varies with type, capacity, and features as well. The perfect purchase of a block machine will enhance output, reduce time and expenses, and improve the construction quality of blocks. There's a hydraulic block machine for longevity, an interlocking block machine for ease of use, and a fully automatic block machine for the highest potential output.

Now that you know about the different kinds of block machines, their details, and production processes, it's time to select a machine that will get your block-making enterprise headed in the right direction. Determine your best fit from here based on production needs and budget.

The QM1200 is the best block making machine in the world when it comes to quality, production, and durability. A machine of this caliber includes a U-shaped vibration system with an anti-mixture color feeding system, an airbag clamping system, imported shock pads, and the capability of producing 10,000 blocks per day.

Whether it's paving stones or hollow blocks—or any concrete creation in between—the QM1200 has the reliability and throughput of production to meet such modern construction needs. Easy to maintain, affordable function, and up-to-capacity production make this machine a necessary part of any block making operation.

This cuber system is suitable for stacking cured blocks. Generally, it is set independently near the curing yard, and the cured products can be stacked on the spot. It also can be connected directly with block production line to realize the online cuber.

The Terrazzo Tile Machine QPR600-6 is a highly efficient and versatile solution for producing premium terrazzo tiles. Utilizing advanced technology, it ensures precise mixing, molding, and compaction to deliver consistent, high-quality results. This machine is ideal for both small and large-scale production, capable of handling various tile sizes and designs. Built with durability and low maintenance in mind, the QPR600-6 is a reliable choice for businesses aiming to produce decorative, high-quality tiles at competitive prices. Optimized with imported Italian technology, its rotating-disk operation model allows for independent movement, ensuring stability and efficiency. The unique design also allows for further processing of tiles, such as sandblasting, washes, archaizing, and brushed finishes, as well as the production of chromatic or top-colored tiles.

The Road Construction High-Speed Paver Laying Machine is engineered for efficient and rapid asphalt application, ensuring smooth, durable road surfaces. With advanced technology, it combines high-speed operation with precise, consistent results. Built for large-scale paving projects, its robust design minimizes downtime and maximizes productivity. Perfect for highways, roads, and infrastructure projects, this machine also offers versatility in laying various types of bricks, including concrete pavers, water-permeable pavement, and sintered road bricks. It can easily cover 400 to 500 square meters daily, making it an excellent choice for municipal engineering, garden construction, and other paving applications.

The Concrete Batching Machine QPLD1600 3200 2400IV is engineered for efficient and precise measurement and mixing of concrete ingredients. Offering various configuration options, this machine provides flexible solutions to meet diverse batching requirements. It guarantees accurate proportions of aggregates, cement, and water, ensuring consistent and high-quality concrete production. With its durable construction, it is perfectly suited for high-volume operations and can easily integrate into larger concrete production systems. The QPLD1600 3200 2400IV is user-friendly, reduces material waste, and enhances productivity in any concrete manufacturing facility.

The QPL Series Concrete Batching Machine and mixer are fully automated, designed for seamless operation. Featuring electronic cumulative measurement and PLC centralized control with a digital display, the system ensures high measurement precision, quick mixing speeds, and superior reliability. The feeding equipment is highly adaptable, compatible with various machines such as loaders, belt conveyors, grab buckets, and horizontal push systems.

/ / : +86-18150503129

Marketing Center : No.11,Zhitai Road,Quanzhou Economy&Technique Development Zone,Fujian